26.02.2019

26.02.2019

VEMoDiAC – monitor motors in the digital world of industry 4.0

Innovation for your asset management. Increasing energy efficiency. Predictive Maintenance

Our Digital Asset Center VEMoDiAC makes your motors fit for Industry 4.0

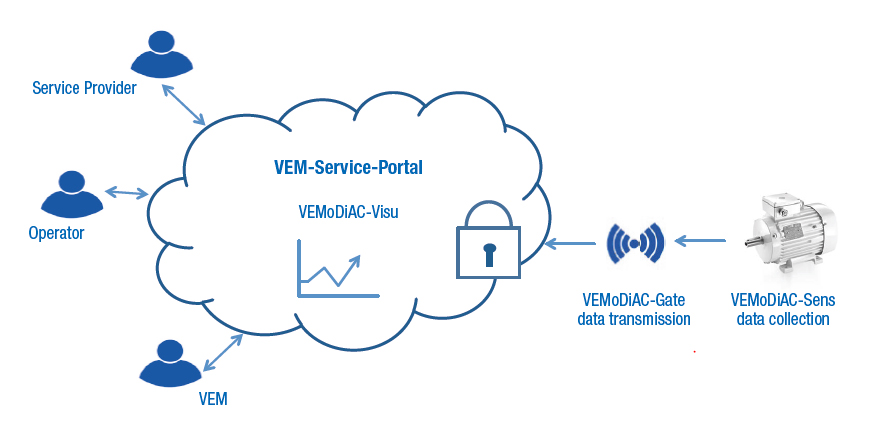

All over the world millions of direct on line (D.O.L) operated motors are running without being monitored. Operators cannot track current energy consumption, and they are not informed about an imminent machine failure. VEM has developed a simple and comprehensive system for motor monitoring that enables you to run your motors more efficiently.

Higher efficiency and availability of your units with motor monitoring

Out of this requirement we developed VEMoDiAC which is a Condition Monitoring system for real time monitoring of your motors. VEM makes use of the advantages of digitalisation and introduces it into the energetic world of mains-operated (D.O.L) motors.

Thanks VEMoDiAC individual equipment can be integrated into an assets network where each motor can be local and independently monitored. This enables the operator to recognize an imminent failure at an early stage, thus saving considerable costs for potentially necessary repairs or maintenance.

VEMoDiAC-Sens: Condition Monitoring by VEM

Measurement accuracy

The measurement unit is directly installed on the motor. The inbuilt sensors offer real-time insights, high degree of accuracy of active power measurement (<5 % measurement error) and conformity to ISO 50001.

Sustainability

Sustainability is guaranteed by the internal power supply and the deliberate choice to build the system without a battery supply, leading to long operating life and reduced cabling work.

Simple and intuitive configuration

The intervals of data transmission can be set individually.

- Commissioning via NFC (App available for IOS and Android)

- Easy access (RFID, QR, NFC)

- Communication to the gateway via WiFi

VEMoDiAC-Sens increases the efficiency and availability of your asset.

VEMoDiAC-Gate

The VEMoDiAC-Gate collects measurement data and transmits it to VEMoDiAC-Visu. If desired it is also possible to evaluate data locally only.

- Communication: internet connection via Ethernet, WiFi or 4G

- Connection: up to 254 devices can be connected with a single VEMoDiAC-Gate

- Transmission of data optional via OPC-UA-Server

VEMoDiAC-Visu

VEMoDiAC-Visu displays the status of your unit. The cloud platform stores, exports, displays and analyses all measurement data collected by VEMoDiAC-Sens. Extensive algorithms evaluate the measurement data and determine the current state of the motor. This allows to plan future maintenance works.

VEMoDiAC-Visu is integrated into the VEM-Service-Portal. There you can have the latest and most important information about your drive system, such as drawings, CAD-models, spare parts, schedules, notifications and alarms.

The prototypes are currently being tested and the product will be on market by the end of 2019.